- By Lanner

- In Customer Stories

- Posted 16/06/2020

The NeroGiardini brand credits its success on the quality production of their shoes and accessories and the reputational aspect of being ‘Made in Italy’. The trade-off for this quality is longer production times than competition. B.A.G. Spa, owner of the NeroGiardini brand, have invested in their supply chain strategy to compensate and are now offering customers rapid replenishment, meaning retailers need hold far less stock without risk of meeting consumer demand.

NeroGiardini is located in the heart of the Marche footwear district and is successfully led by Enrico Bracalente, who has created an organisational model, unique in its kind, which guarantees work for over 2,000 employees, producing 15,000 pairs of shoes per day. The model uses a network of experienced shoemakers, which NeroGiardini then pulls together using an innovative supply chain logistics model.

“Years later I can say that I was brave when I decided not to relocate production, but to continue using the experienced shoemakers of the region. I knew I had to face a complex challenge. I organised myself and managed to build a network of highly specialised companies in the Fermo-Macerata district that produce exclusively for us, the NeroGiardini Shoes Valley” says Bracalente.

After years of strong growth within Italy, NeroGiardini was ready to change its market strategy by focusing on foreign growth, with the aim of tackling international markets. To support this growth, a new logistics centre was needed to meet the increased demand and new

supply chain challenges.

To manage the project, NeroGiardini turned to

UTECO-CONTEC, a leader in the design and construction of industrial automation systems, which would be needed to ensure all products could be managed within the logistics hub in the most efficient and cost-effective way.

Given the importance of the project, the high level of complexity and its economic, organisational and managerial implications, it was decided predictive simulation would be used to evaluate the new logistic centres automated systems. For this, UTECO-CONTEC selected Lanner’s

WITNESS predictive simulation software and the skills of our Italian partner, Studio Zeta.

The Strategic Objective of the Project

"After years of strong growth in the Italian market, we needed to expand our market reach further afield. We have an ambitious program: 77% of our turnover comes from our Italian markets, and we are now looking to expand across Europe, while maintaining all production in Italy. As part of our long-term plan, the goal is to enter the ranking of the Top Ten European producers, which is currently led by English brand, Clarks," explains Bracalente.

To create the new logistics centre, B.A.G. Spa purchased the area of the former Sadam Sugar Factory in Campiglione di Fermo, an area of 230,000 square meters, in the Marche footwear district, which is conveniently connected to a large road network that was perfect for penetrating central Europe.

"A 50 million Euro investment was made to enable us to enter the international markets, with the creation of our new headquarters, outlet and the logistics centre."

The Tactical Objective

The new logistics hub is designed to serve as a centralised distribution centre for all NeroGiardini business customers, with an ambitious guarantee of 24-hour restocking for the Italian market and 96 hours for the rest of the continent. A promise that creates a challenging but highly valuable supply chain network for NeroGiardini customers.

To meet these delivery objectives, highly automated processes needed to be implemented, with practically zero margins for errors, time and space, crucial when working to such tight restocking time frames.

Responding to market trends and how retailers operate, Bracalente says “Today customers prefer to buy less stock at the beginning of the season and then buy more in response to demand. To allow our customers to be more flexible, we can guarantee they can restock at maximum speed. The strength lies in us taking on the market understanding and having faith we will produce the correct products throughout the season to meet this demand and allowing retailers to replenish effectively even during sales periods. "

This guarantees a high product rotation index, a high sell-out percentage and high profitability at the end of the season. With the new logistics hub, NeroGiardini offers a unique service in Europe, aiming to conquer more and more markets.

Simulating Complex Operations

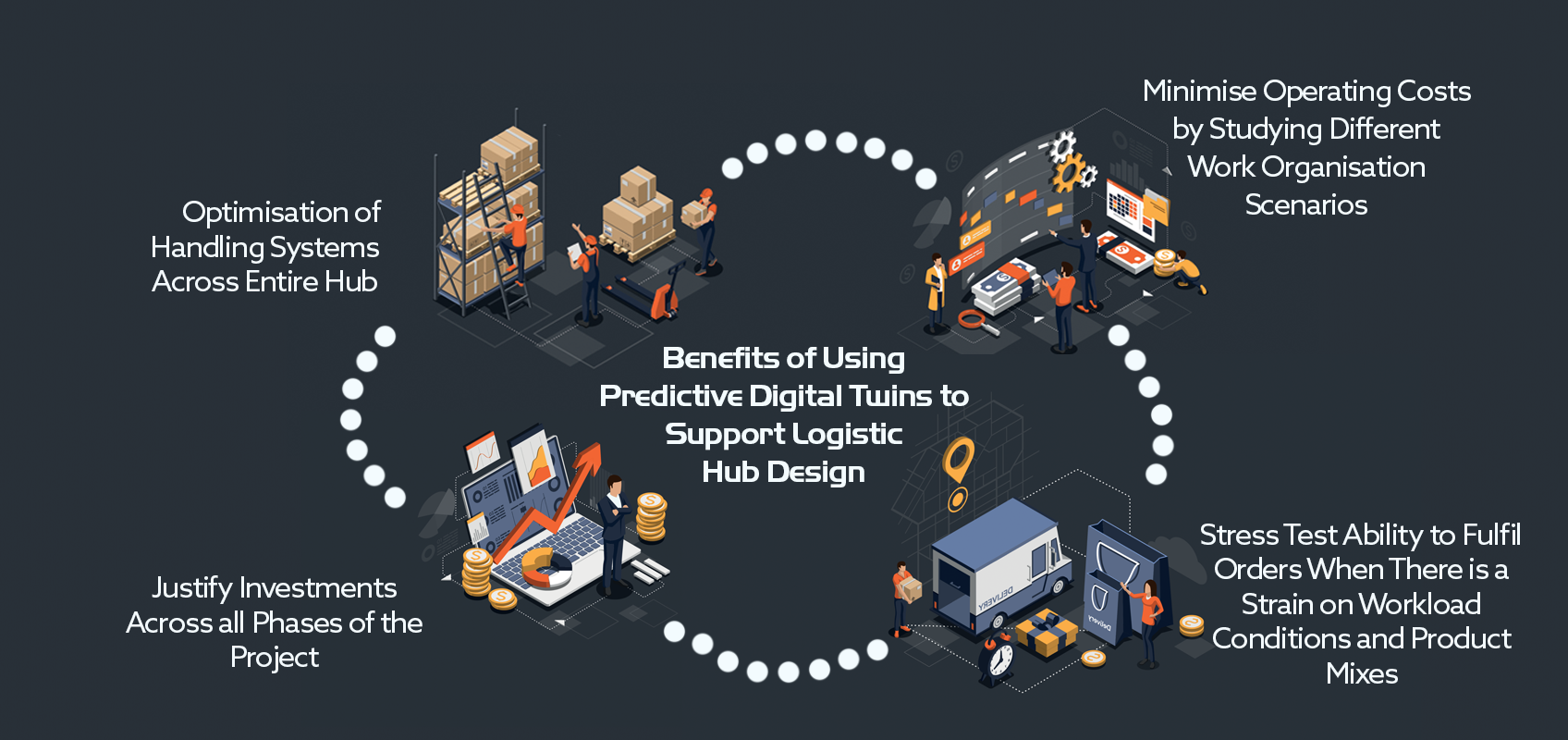

Given the highly complex processes NeroGiardini wanted to implement across their logistics centre, and the associated investment costs, UTECO-CONTEC worked with Studio Zeta to create a

predictive digital twin of the automated systems, layouts and workflows being proposed.

Within this virtual world, all proposed scenarios could be tested and validated, before any large investment was made. It gave NeroGiardini a visual roadmap of how their new logistics hub would look and operate, ensuring all objectives could be met in the most efficient way. This level of insight is an invaluable tool when designing and implementing a project of this scale.

Using Lanner’s predictive simulation technology, Studio Zeta were able to validate the automated system design and optimise technical solutions, demonstrating and proving the validity of possible alternative solutions which may not have been considered.

The Results Achieved

The predictive digital twin of the automated systems within the new logistics hub gave NeroGiardini a deeper understanding of how their systems would work. Before the model was built, some assumptions were made regarding optimum layouts and processes however Studio Zeta were able to identify several areas for improvement, while highlighting potential bottlenecks and alternative solutions.

The model was also used to define the overall capacity of the entire hub and anticipate operational critical issues. This has given NeroGiardini the confidence to invest in the correct automated systems, ensuring their business growth objectives can be met as they expand into the European market.